Page 580 - Demo

P. 580

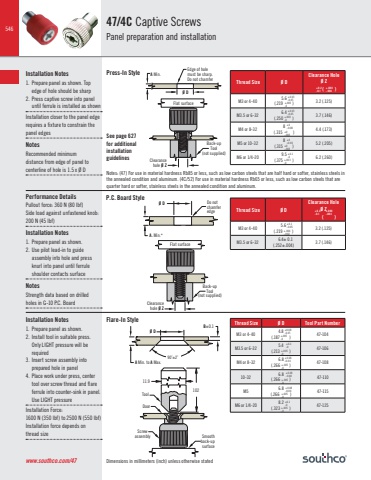

546Dimensions in millimeters (inch) unless otherwise stated47/4C Captive ScrewsPanel preparation and installationClearancehole Ø ZBack-upTool(not supplied)Flat surfaceØ DEdge of holemust be sharp.Do not chamferInstallation Notes A Min.1. Prepare panel as shown. Topedge of hole should be sharp2. Press captive screw into paneluntil ferrule is installed as shownInstallation closer to the panel edge requires a fixture to constrain the panel edgesNotesRecommended minimumdistance from edge of panel to centerline of hole is 1.5 x Ø DPerformance DetailsPullout force: 360 N (80 lbf)Side load against unfastened knob: 200 N (45 lbf)Installation Notes 1. Prepare panel as shown.2. Use pilot lead-in to guideassembly into hole and pressknurl into panel until ferruleshoulder contacts surfaceNotesStrength data based on drilled holes in G-10 P.C. BoardInstallation Notes 1. Prepare panel as shown.2. Install tool in suitable press.Only LIGHT pressure will berequired3. Insert screw assembly intoprepared hole in panel4. Place work under press, centertool over screw thread and flareferrule into counter-sink in panel.Use LIGHT pressureInstallation Force: 1600 N (350 lbf) to 2500 N (550 lbf)Installation force depends on thread sizeØ D90˚±2˚ B±0.1A Min. to A Max.Smoothback-upsurfaceToolDoorScrewassembly10211.9Ø DA. Min.*Do not chamferedgeFlat surfaceClearancehole Ø ZBack-upTool(not supplied) Thread Size Ø DClearance Hole Ø Z ( )M3 or 4-40 5.6 (.219 ) 3.2 (.125)M3.5 or 6-32 6.4(.250 ) 3.7 (.146)M4 or 8-32 8 (.315 ) 4.4 (.173)M5 or 10-32 8 (.315 ) 5.2 (.205)M6 or 1/4-20 9.5 (.375 ) 6.2 (.260) Thread Size Ø DClearance Hole Ø Z ( )M3 or 4-40 5.6 (.219 ) 3.2 (.125)M3.5 or 6-32 6.4± 0.1 (.252±.004) 3.7 (.146) Thread Size Ø D Tool Part NumberM3 or 4-40 4.8 (.187 ) 47-104M3.5 or 6-32 5.4 (.213 ) 47-106M4 or 8-32 6.8 (.266 ) 47-10810-32 6.8 (.266 ) 47-110M5 6.8 (.266 ) 47-115M6 or 1/4-20 8.2 (.323 ) 47-125P.C. Board StyleFlare-In Stylewww.southco.com/47Notes: (47) For use in material hardness Rb85 or less, such as low carbon steels that are half hard or softer, stainless steels in the annealed condition and aluminum. (4C/52) For use in material hardness Rb65 or less, such as low carbon steels that are quarter hard or softer, stainless steels in the annealed condition and aluminum.Press-In StyleSee page 627 for additional installation guidelines+0.03-0.05 +.003-0+0-0.08+0-.003+0.1-0+.003-0+0.2-0.1+.008-.004 +.003-0+0.03-0.05+0-0.08+0-.003+0.1-0.05+.004-.002+0.08-0.05+.005-0+0.08-0.04+.005-0+0.1-0+.005-0+.005-0+0.1-0+0.08-0.04+.005-0+0.08-0.04+.005-0+0.2-0.1+.008-.004