Page 589 - Demo

P. 589

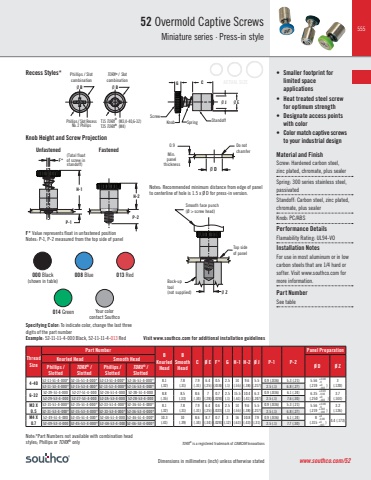

555Dimensions in millimeters (inch) unless otherwise statedSpecifying Color: To indicate color, change the last three digits of the part number Example: 52-11-11-4-000 Black, 52-11-11-4-013 Red000 Black(shown in table)008 Blue 013 Red014 Green Your colorcontact Southco52 Overmold Captive ScrewsMiniature series · Press-in styleKnob Height and Screw ProjectionRecess Styles*F* Value represents float in unfastened positionNotes: P-1, P-2 measured from the top side of panelNote:*Part Numbers not available with combination head styles; Phillips or TORX® onlyØ EStandoff SpringScrewKnobØ JØ B Ø BTORX® / SlotcombinationPhillips / SlotcombinationPhillips / Slot RecessNo. 2 PhillipsT15 TORX® (M3,4-40,6-32)T25 TORX® (M4)G C• Smaller footprint for limited space applications• Heat treated steel screw for optimum strength• Designate access points with color• Color match captive screws to your industrial designMaterial and FinishScre Hardened carbon steel, zinc plated, chromate, plus sealer Spring: 300 series stainless steel, passivated Standoff: Carbon steel, zinc plated, chromate, plus sealer Knob: PC/ABSPerformance DetailsFlamability Rating: UL94-VOInstallation NotesFor use in most aluminum or in low carbon steels that are 1/4 hard or softer. Visit www.southco.com for more information.Part NumberSee tableMin. panel thicknessØ D 0.9 Do not chamferBack-uptool(not supplied)Smooth face punch(Ø > screw head)Ø ZTop side of panelNotes: Recommended minimum distance from edge of panel to centerline of hole is 1.5 x Ø D for press-in version. P-1H-1 F*(Total float of screw in standoff)Unfastened FastenedP-2H-2www.southco.com/52ACTUAL SIZEVisit www.southco.com for additional installation guidelinesTORX® is a registered trademark of CAMCAR InnovationsThreadSizePart NumberBKnurledHeadBSmoothHeadC Ø E F* G H-1 H-2 Ø J P-1 P-2Panel PreparationKnurled Head Smooth HeadPhillips / Ø D Ø ZSlottedTORX® /SlottedPhillips /SlottedTORX® /Slotted4-40 52-11-51-4-000* 52-15-51-4-000* 52-13-51-4-000* 52-16-51-4-000* 8.1(.32)7.8(.31)7.9(.31)6.4(.25)0.5(.018)2.5(.1)14(.55)9.6(.38)5.5(.217)0.9 (.036) 5.3 (.21) 5.56 (.219 ) 352-11-53-4-000* 52-15-53-4-000* 52-13-53-4-000* 52-16-53-4-000* 2.5 (.1) 6.8 (.27) (.120)6-32 52-29-51-4-000 52-27-51-4-000 52-2A-51-4-000 52-28-51-4-000 8.8(.35)8.5(.33)8.6(.34)7(.28)0.7(.028)2.5(.1)15.5(.61)10.4(.41)6.3(.247)0.9 (.036) 6.1 (.24) 6.35 (.250 )3.752-29-53-4-000 52-27-53-4-000 52-2A-53-4-000 52-28-53-4-000 2.5 (.1) 7.6 (.30) (.144)M3 X0.552-31-51-4-000* 52-35-51-4-000* 52-33-51-4-000* 52-36-51-4-000* 8.1(.32)7.8(.31)7.9(.31)6.4(.25)0.6(.023)2.5(.1)14(.55)9.6(.38)5.5(.217)0.9 (.036) 5.3 (.21) 5.56 (.219 )3.252-31-53-4-000* 52-35-53-4-000* 52-33-53-4-000* 52-36-53-4-000* 2.5 (.1) 6.8 (.27) (.126)M4 X0.752-49-51-4-000 52-45-51-4-000* 52-4A-51-4-000 52-46-51-4-000* 10.3(.41)10(.39)8.6(.34)8.7(.34)0.7(.028)3(.12)16(.63)10.8(.43)7.9(.31)0.9 (.036) 6.1 (.24) 8 (.315 ) 4.4 (.173) 52-49-53-4-000 52-45-53-4-000* 52-4A-53-4-000 52-46-53-4-000* 2.5 (.1) 7.7 (.30)+0-0.08+0.08-0+0.03-0.00+0.08-0+0-.003+0-.003+0-.003+.003- .000