Fasteners

-

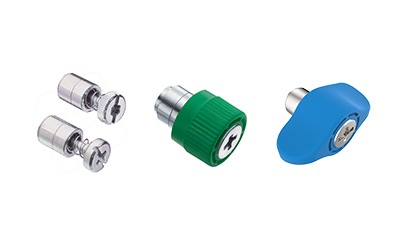

Captive Screws

- Stays secure to the panel, preventing loss and protecting sensitive electronics

- Tool recess, thread size and installation options to suit any application

- Spring ejection and self-aligning float provide easy installation

-

DZUS® Quarter-Turn Fasteners

- Quickly secures and releases with a 90 degree turn

- Stays captive to the panel, providing ease of use and preventing lost hardware

- Provides a strong, consistent clamping force with repeated operation

-

Quick Access Fasteners

- Provides quick access for hinged or removable panels

- Latches into thru or blind holes

- Locates sliding panels

-

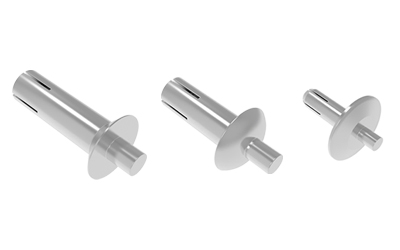

Rivets

- Available in six different diameters and numerous lengths

- Materials and sizes to suit a range of enviormental and strength requirements

- Tamper-resistant/tamper-evident designs resist being driven through or drilled out

-

Inject/Eject Mechanisms

- Ergonomic insertion, extraction and locking of electronic modules

- Adheres to industry standards for robustness and hot swap capability

- Wide range of designs to match popular connector pin densities

-

Gaskets

- Seal out dust and moisture

- Minimize rattles due to vibration

- Compensate for surface contour irregularities

Frequently Asked Questions (FAQ's)

What are fasteners?

Fasteners are hardware devices that mechanically join or affix two or more objects together. Think of them as the "glue" of the mechanical world, but instead of adhesive, they use physical force to hold things in place. They come in a vast array of shapes, sizes, and materials, each designed for specific applications and load requirements. They're essential for everything from assembling cars to putting together electronics.

What type of fasteners are available?

Fasteners range from traditional options like screws, bolts, and rivets, to specialty hardware like captive screws, quarter-turn, and inject/eject mechanisms. Each type of fastener caters to specific needs, and there's one for every job, varying in material, size, and design.

How do I choose the right fastener for my project?

Choosing the right fastener depends on several crucial factors:

Material Compatibility: Ensure the fastener material is compatible with the materials you're joining to prevent corrosion or damage.

Load Requirements: Consider the weight and stress the fastener will bear. Select a fastener with sufficient strength and shear resistance.

Application Environment: Factor in temperature, humidity, and exposure to chemicals or vibrations. Choose corrosion-resistant fasteners for outdoor or harsh environments.

Accessibility: Determine if you need access to both sides of the joint. Blind fasteners are used when access is limited.

Assembly and Disassembly: Decide if the joint needs to be permanent (rivets) or easily disassembled (quarter-turn/captive screws).

Size and Thread: Select the appropriate diameter, length, and thread type for your project.

Head Style: Choose a head style that's compatible with your tools and provides the desired aesthetic.

Cost: Balance performance requirements with budget constraints.

Where can I purchase fasteners?

At Southco, we offer a wide array of reliable and high-quality fasteners engineered for various industrial, interior, and exterior applications. Our selection includes:

Secure Connections: Designed for robust and lasting fastening.

Diverse Range: From standard to quick-access options, in various materials and sizes.

Built to Last: Engineered for durability in demanding conditions.

Easy Access: Purchase conveniently through our website or global distributor network.

Browse our extensive catalog to find the perfect fastener for your project or contact our team for expert assistance.