Why the Quarter-Turn Fastener Turns Heads In Automotive Design

Automotive manufacturers are gradually making the transition from solely manufacturing vehicles to taking on more responsibility for the performance of a vehicle over its life cycle. As a result, OEMs are increasingly looking for ways to lower installation costs, and facilitate quick repeatable access to critical vehicle components in order to enable faster service calls. At the same time they are also under pressure to meet consumer demand for superior ergonomics, as motorists continue to seek out convenience.

Amid the rapid pace at which new materials and components are being introduced to automotive design, the quarter-turn fastener has stood the test of time: first patented by William Dzus in the 1930s, and originally designed for the aerospace market, this reliable and proven fastener is a common feature in many vehicles on the road today. Over decades, the value proposition of the DZUS® Quarter-Turn fastener has remained as consistent and stable as the product’s performance itself: fast, repeatable access, no loss in strength under continued operation, retention of hardware in the panel, and therefore faster service calls and lower maintenance costs. The DZUS® Quarter-Turn Fastener remains one of the foremost names in the world of quick release fastening.

A design that ‘just clicks’

Incorporated under the Southco brand through acquisition in 2004, it is the decades-long proven benefits of the quarter-turn fastener that keeps the DZUS brand highly recognized across many industries, including the automotive sector.

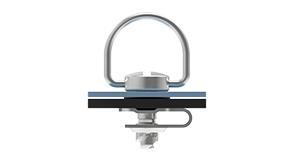

The typical quarter-turn fastener assembly is simple – consisting of a stud and receptacle that firmly holds panels or frames together. The stud being made captive through the use of a retainer washer. Numerous stud lengths and actuation styles are on offer alongside a variety of mounting configurations. Snap-in and clip-on receptacles minimize assembly times and reduce installation costs, and the spring steel design of the receptacle provides a repeatable, grip-tolerant fit. Front-mount press-in receptacles, better suited for soft metals and thermoplastic materials, are also available.

Whatever combination of stud, receptacle and retainer, all varieties of the quick access fastener system are both vibration resistant and easy to unfasten, unlike alternative fastening options which can be prone to wear and /or loosening over time, or which are more complex to install and unfasten. For many engineers, the intuitive design, pre-set clamping force and reassuring click of the DZUS® Quarter-Turn Fastener is all that is needed to know that a device is correctly coupled and secured without the risk of over tightening.

The convenience of the DZUS® Quarter-Turn Fastener is best illustrated when used to fasten underbody noise shields. It has long been perceived that traditional captive nuts, or threaded hole and bolts offer a robust and durable method of fastening the panels of underbody shielding in place. Threaded fastener systems are cheap to buy, but short term savings can come at the expense of long-term maintenance costs. Initial cost savings of using threaded bolts /retained nuts can diminish over time with the additional service and maintenance time taken to fasten and unfasten the system, threads wearing out as well as potential losses from head recess strip-out and the loss of non-retained loose parts.

With a quarter-turn fastener, one simple 90 degree turn triggers quick release, which makes the installation and subsequent re-installation of underbody shields quick and practically effortless. This consistent, repeatable fastening with extended performance in aggressive and demanding environments makes the quarter-turn a viable solution for this and many other similar applications including engine covers, wheel arch liners, trunk tie downs, fuse box covers and tow hitch covers.

Facilitating future vehicle design

Southco continues to develop the design and functionality of the DZUS® Quarter-Turn Fastener, and it remains as important to future vehicle design as it has been across the industries for the last 80 years. Southco is able to develop custom solutions to meet the specific needs of OEM customers systems, manufacturing and service engineers alike, from supplying special finishes and materials to achieve a cosmetic requirement or performance in aggressive environments, to tooling up specific head styles.

Southco's DZUS® Quarter-Turn Fastener series has been providing reliable quick access for the last 80 years, facilitating quick and easy life cycle maintenance.

As future vehicle design will surely continue the need for easy and quick access to critical vehicle components throughout the vehicle’s life cycle, Southco’s DZUS® Quarter-Turn Fastener is well positioned to satisfy the requirements for improved ergonomics and convenience, whilst at the same time ensuring improved profit margins in the long run.

Turning heads for eight decades

Patented at the same time that four-wheel hydraulic brakes, low pressure balloon tires and sunshades were starting to find their way into mainstream vehicle production, the quarter-turn fastener is one innovation that is as important today as it has ever been. As vehicle design continues to evolve, the quality, versatility, and durability of the Quarter-Turn Fastener will continue to fulfill a unique requirement, helping car makers lower installation costs and facilitate quick, repeatable access to critical vehicle components throughout the life cycle of a vehicle.